OUR CAPABILITIES

WHAT WE DO

SCHEDULE CONTROL

SCHEDULE CONTROL

A vital management tool of any project is the project schedule. The accuracy and management of the project schedule determine the pulse and vitality of the project. Our first objective is to develop and document a realistic overall schedule outlining, in general terms, all activities from the feasibility studies to final completion of construction. The master schedule, typically created in a simple bar chart form, provides a “big picture” view of the total project, as well as a foundation for all subsequent schedules.

OPI Phoenix Systems JV then develops detailed schedules that breakdown and examine in greater detail numerous activities that are required to achieve overall project milestones. These schedules are usually organized on a 30-day or 60-day basis to provide short-term “look ahead” schedules for the use of jobsite staff. Such schedules help solve unusually difficult or complex scheduling problems that may occur during the development of a project.

COST CONTROL

COST CONTROL

After the value and fixed costs of the project have been identified and accepted by the client, our cost control system will be implemented to monitor construction costs versus the approved estimate. Beginning with initial subcontract awards, the cumulative amount of committed funds will be monitored closely. From that point forward, data will be continuously compared to the approved estimate and updated.

BUDGET & CONTRACT STATUS REPORT

BUDGET & CONTRACT STATUS REPORT

This report is a combined cost and accounting report that provides cost and billing information delineated by major work divisions. The original estimate is updated to reflect any scope development changes. Work in place, off-site material storage, reserves withheld, previous billing and current payments per trade division are represented in the summary analysis. This report is issued monthly with the OPI Phoenix Systems JV application for payment and represents a comprehensive one-page summary of the client’s total cost and payment position on the project.

QUALITY CONTROL

QUALITY CONTROL

The OPI Phoenix Systems JV quality control program begins during the pre-construction phase and continues throughout the entire project. Using our prior experience on similar projects, OPI Phoenix Systems JV (under the leadership of the project manager), will work closely with the client during the design period to review design features and eliminate potential problems.

This effort will be followed by a thorough review of subcontractor shop drawings by the Project Engineer to assure that trade contractor’s planning conforms to the contract requirements. Once this review has been completed, problem areas are first discussed with the contractors. The Project Manager will then carefully review these items with the trade contractors so there is a complete and clear understanding of installation techniques and quality control standards.

The Project Manager oversees the inspection of shop fabrication and field installation. Where appropriate, materials and fabricated items will be inspected at the manufacturer’s shops or plants, and again on site, to assure that all materials are satisfactory prior to installation.

Additionally, the Project Manager performs final inspections, prepares the punch-list, and expedites the completion of work specified on such lists.

PROJECT CLOSEOUT

Punchlist

OPI Phoenix Systems JV and the team will conduct inspections of the completed facility, and compile and complete all necessary punch-list items.

Facility Management

We will work with your facilities management team to educate them on the operation and maintenance of your new facility.

Documentation Control

We will monitor receipt of all operational manuals, as-built drawings, permits, affidavits, warranties and other required documents.

Lien Certifications

We will compile a summary of all project expenditures for your information and assist in fulfilling all release of lien certification requirements.

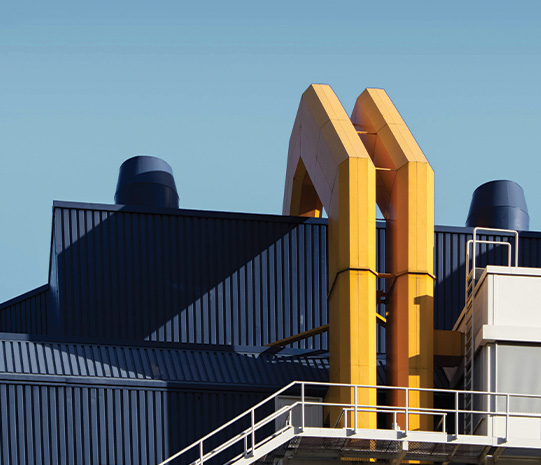

Welding

Warehouses

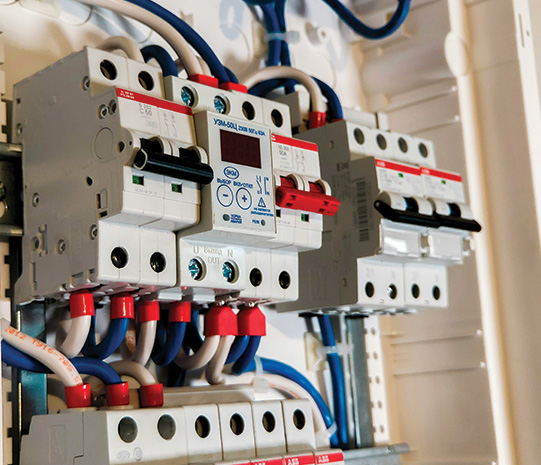

Electrical Wiring

Plumbing

Roofing

Painting

Drywall